29 October 2025

The information contained within this announcement is deemed to constitute inside information as stipulated under the Market Abuse Regulation ("MAR") (EU) No. 596/2014, as incorporated into UK law by the European Union (Withdrawal) Act 2018. Upon the publication of this announcement, this inside information is now considered to be in the public domain.

Artemis Resources Limited

("Artemis" or "The Company")

Drill Update Titan East

5m @ 13.1g/T Gold Intersected Within 20m Mineralised Zone in First Drill Hole to Test New Target at Titan East

Highlights

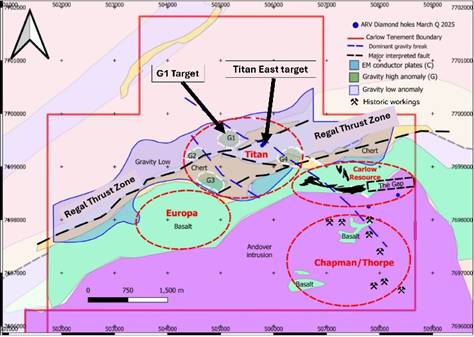

· First Reverse Circulation (RC) drill hole to test an interpreted shear zone at the Titan East Prospect produced an outstanding intersection of 5m @ 13.1g/t gold from 132m down hole in 25ARRC006. There is no previous drilling along the shear zone.

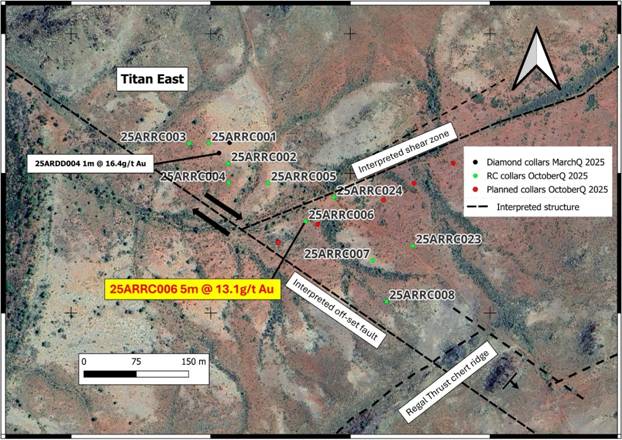

· The high-grade gold intersection is associated with vein quartz within a 20m mineralised interval which includes other elevated gold assays between 0.1g/t Au up to 0.78g/t gold.

· Assay results awaited from a second RC hole, 25ARRC024, drilled 50m east of 25ARRC006 which intersected several intervals of vein quartz starting from 28m depth.

· The interpreted NE trending shear zone which hosts the gold intersected in 25ARRC006 is covered by transported sediments and is parallel to the Regal Thrust, which outcrops as a prominent chert ridge 300 metres to the south.

· Diamond drilling is planned to start late November to determine orientation of the quartz veins and potential for extensions along the interpreted shear zone.

Artemis Resources (ASX: ARV) (Artemis or the Company) is pleased to report a high-grade gold intersection in the first RC hole testing an interpreted NE trending shear zone at the Titan East Prospect, 1.5km west of the Carlow gold-copper resource[1].

Significant intersection - 25ARRC006 (all assays received):

· 5m @ 13.1 g/t Au from 132-137 m, including 3m @ 20.9 g/t Au from 133m.

· The high-grade gold intersection is associated with abundant vein quartz.

· High-grade gold occurs within a 20m interval of elevated gold values from 131m.

Step-out hole - 25ARRC024 (assays pending):

· Several intervals of vein quartz identified between approximately 28m and 57m.

· Vein quartz occurs within altered and sheared ultramafic, mafic and sedimentary units.

· Hole 25ARRC024 also appears to have drilled through the interpreted shear zone.

Jozsef Patarica, Executive Director, commented:

"Titan East is a brand-new, shear-hosted gold target just 1.5km from Carlow. Hitting 5m @ 13.1 g/t Au in the first RC hole is an excellent start and supports our strategy to build scale around Carlow by finding additional, nearby gold resources. Given the very encouraging gold intercept we have arranged for diamond drilling to begin in late November to define the true widths and orientation."

"While we await more assays from the RC drilling, these results have greatly increased our confidence in the potential at Titan and the wider Carlow area. Apart from the three diamond holes drilled in the March quarter which returned a very promising result of 1m @ 16.6g/t Au and the recent 18 RC drill holes, Titan is completely untested."

Titan East

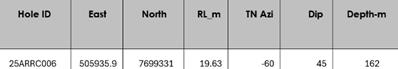

Titan is a large, structurally complex area along the northern side of the Regal Thrust which outcrops as a regional chert ridge offset by NW-trending cross cutting faults. The central part of Titan is largely covered by transported cover which limits surface geochemical exploration.

During September and early October, Artemis completed 18 widely spaced RC holes (1,758m) across two target areas at Titan. The targets tested by the RC drilling are Titan East, at the intersection of two major structural trends (refer to Figures 1 and 2) and the G1 gravity anomaly, 700m west of Titan East.

Previous March-quarter diamond drill holes (25ARDD003-005) and the recent RC drill holes intersected sheared and altered ultramafics, sediments, mafic volcanics and a porphyry sill. Assay results are pending for many of the recent RC holes at Titan including 25ARRC024 drilled 50m east of 25ARRC006. 25ARRC024 intersected several intervals with vein quartz between approximately 28m and 57m down hole within altered ultramafic, mafic units and sediments.

A further update will be provided once all RC drill hole assays are received. (Refer Figures 1-3).

.

Figure 1: Simplified geology of Carlow area showing Regal Thrust Zone, Carlow resource outline and Titan East and G1 drill targets. Also showing location of the Europa and Chapman/Thorpe satellite exploration prospects

Figure 2: Satellite image of Titan East showing location of RC drill holes, two main structural trends (Interpreted Shear Zone and Offset Faults) and base of outcropping Regal Thrust chert ridge

Figure 3: Preliminary cross section through RC drill holes 25ARRC006 and 25ARRC024, looking North

Table 1: RC hole 25ARRC006 - elevated and high-grade gold assays for 1m and 2m sample intervals, 131m-151m

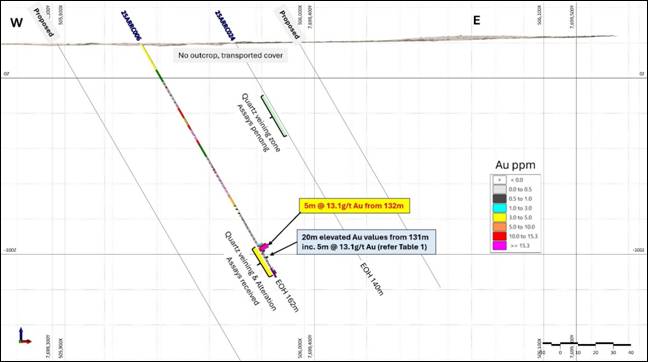

| HOLE | EAST | NORTH | Grid | RL_m | DIP | TN_Azi | Depth_m |

| 25ARRC006 | 505935.9 | 7699331 | MGA94_Zone_50 | 19.63 | -60 | 45 | 162 |

Table 2: Drill hole parameters for RC hole 25ARRC006

Next steps

· Receive and report outstanding RC drill hole assays, including for hole 25ARRC024.

· Commence diamond drilling (targeting late November) to determine mineralised vein orientations, true widths and strike/plunge potential.

· Integrate results from Titan East and G1 Target into Carlow strategy for follow-up drilling.

For more information, please visit www.artemisresources.com.au

This announcement was approved for release by the Board.

|

Tel: +44 20 3829 5000

|

Competent Person Statement

The information in this report that relates to Exploration Results was compiled by Mr Julian Hanna, a Competent Person who is a member of the Australasian Institute of Mining and Metallurgy (MAusIMM). Mr Hanna is Technical Director of Artemis Resources Ltd and has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the 'Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves". Mr Hanna consents to the inclusion in this report of the matters based on his information in the form and context in which it appears.

No New Information

To the extent that this announcement contains references to prior exploration results which have been cross referenced to previous market announcements made by the Company, unless explicitly stated, no new information is contained. The Company confirms that it is not aware of any new information or data that materially affects the information included in the relevant market announcements and, in the case of estimates of Mineral Resources, that all material assumptions and technical parameters underpinning the estimates in the relevant market announcements continue to apply and have not materially changed.

Forward Looking Statements

This announcement contains historical facts, interpretations and statements relating to the Company's current exploration projects, drill targets, plans, estimates, objectives, and strategies which are forward-looking statements. Such forward-looking statements involve known and unknown risks, uncertainties and other important factors beyond the Company's control that could cause the actual results, performance, or achievements of the Company to be materially different from future results, performance or achievements expressed or implied by such forward-looking statements. Accordingly, any reliance you place on such forward-looking statements will be at your sole risk and the Company expressly disclaims any obligation or undertaking to disseminate any updates or revisions to any forward-looking statements contained in this announcement to reflect any changes in its expectations with regard thereto or any change in events, conditions or circumstances on which any statement is based. The information contained in this announcement is subject to change without notice. No representation or warranty, express or implied, is given as to the accuracy, completeness or fairness of the information or opinions contained in this announcement and no liability is accepted by the Company or any of its directors, members, officers, employees, agents, or advisers for any such information or opinions.

_____________________________________________________________________________

About Artemis Resources

Artemis Resources (ASX/AIM:ARV) is a gold and copper focused resources company with a highly attractive suite of projects including projects in Western Australia's underexplored North Pilbara Gold Province and at the Cassowary Exploration Project located 440km east of Kalgoorlie in Western Australia.

· Attractive projects:

o Gold/Copper - Karratha Gold Project (100%) multiple prospects incl: Carlow, Titan, Thorpe

o Copper/Gold - Cassowary Exploration Project - large IOCG type targets

o Paterson Gold/Copper Project - adjacent to Havieron Mine (owned Greatland Gold)

o Lithium - Artemis/Greentech Lithium JV: Mt Marie, Kobe, Osborne

· Highly strategic location: Tier 1 jurisdiction, close proximity to major hub at Karratha including regional rail and road infrastructure, administrative centre and Dampier Port

· Significant exploration upside: highly prospective tenure package in the Pilbara Region of Western Australia which is rapidly emerging gold province dominated by >12Moz Au Hemi Project

· Mineral Resource with growth potential: existing high-grade gold-copper Mineral Resource at Carlow

· Established processing site at Radio Hill: strategically located, fully permitted

· Cassowary Exploration Project: Artemis holds a granted 341km2 exploration licence covering the large, interpreted Cassowary Intrusion prospective for IOCG type copper/gold and has four other exploration licence applications to cover other interpreted intrusions within a 30-40km wide interpreted rift zone

Appendix 1 JORC Table

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections)

| Criteria | JORC Code explanation | Commentary |

| Sampling techniques | · Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. · Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. · Aspects of the determination of mineralisation that are Material to the Public Report. In cases where 'industry standard' work has been done this would be relatively simple (eg 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information. | RC Drilling · Reverse Circulation drilling (RC) at Titan East was undertaken to obtain samples that were laid out in one metre intervals. · Samples submitted for assay were either composites of two metre lengths, or single metre samples. Spacing determined by logging geologist. · Single metre samples are ~ 3kg samples obtained directly from the secondary port of the cone splitter. · Composites were produced by representatively sampling each individual drill spoil pile to be included in the composite. · Sampling of the drill spoil for assay was undertaken by scoop method into numbered calico bags. · Samples were dispatched to ALS Global Laboratories in Perth for analysis. · Analysis included: • Au-AA26 - Au 50g FA AA finish • ME-MS61 - 48 elements Ultra-Trace Four-Acid Digestion with ICP MS and ICP-AES

|

| Drilling techniques | Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face- sampling bit or other type, whether core is oriented and if so, by what method, etc). | · Drilling was completed using the RC method. A standard RC hammer bit was used, with chip samples returned within the drill pipe and recovered through a cyclone. · Holes were drilled towards North at various dips and to varying depths. All holes were surveyed using a North Seeking Gyro for downhole surveys undertaken at 5 or 10m intervals. |

| Drill sample recovery | · Method of recording and assessing core and chip sample recoveries and results assessed. · Measures taken to maximise sample recovery and ensure representative nature of the samples. Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. | · The geologist visually assessed and digitally recorded drill sample recoveries during the program. Recoveries were overall very good with 98% of the sample intervals recovered >75%, discounting overburden · Drill cyclone was cleaned regularly between holes if required to minimise down hole or cross-hole contamination. · Samples were almost entirely dry, with little water encountered in the drilling. No relationship between sample recovery and grade has been recognised. |

| Logging | · Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. · Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. The total length and percentage of the relevant intersections logged. | RC Drilling · All drill holes have been logged, using sieved rock chips from the drill samples to industry best standards for lithology, alteration, mineralisation using a specific set of logging codes to ensure consistency in logging. · Logging has been quantitative in nature. · The level of geological detail is commensurate with nature and limitations of this exploratory drilling technique. · The current drill-spacing is insufficient for Resource Estimation. · All sampling data has been stored directly into an in-house developed Access data management system. · All drill holes were logged in full. · All logging and sampling undertaken under the supervision of a qualified geologist.

|

| Sub-sampling techniques and sample preparation | · If core, whether cut or sawn and whether quarter, half or all core taken. · If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. · For all sample types, the nature, quality and appropriateness of the sample preparation technique. · Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. · Measures taken to ensure that the sampling is representative of the insitu material collected, including for instance results for field duplicate/second-half sampling. · Whether sample sizes are appropriate to the grain size of the material being sampled. | RC Drilling RC drill spoil samples were collected by traversing each sample pile systematically by scoop to obtain similar volumes of representative material for either a single metre interval or a composite interval of 2m. This is regarded as a fit for purpose sampling regime for the type of drilling and the current stage of exploration. · The drill samples were almost entirely dry, with very few moist samples. · Where composite samples were taken, equal amounts of sample were taken from each of the constituent sample piles. · Field duplicate sampling was also undertaken at an approximate ratio of 1:25. · The samples were then sent to ALS Laboratory for sample preparation and analysis. · The sample sizes are appropriate for the style of mineralisation being investigated.

|

| Quality of assay data and laboratory tests | · The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. · For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established. | RC Drilling · Samples were dispatched to ALS Global Laboratories in Perth for analysis. · Samples underwent High Grade Fire Assay fusion (50 g) - lead flux with Ag collector and Au amount determined by ALS method Au-AA26 and for multi-element analysis a four-acid "near" total digest (HF-HNO3- HClO4) has been undertaken on a 0.25 g sub-sample to quantitatively dissolve most geological materials, ALS method ME-MS61. · All finalised assay certificates signed off by qualified assayer. · ALS Global Ltd is an ISO certified organisation with industry leading quality protocols. · The analytical technique used for gold is considered a total assay technique. · For multi-element analysis a four-acid digest has been undertaken on a 0.25 g sub-sample to quantitatively dissolve most geological materials, with analysis via ICP-MS + ICP-AES. · Certified Reference Materials (CRM) including three different gold grade standards and blanks have been submitted within the samples stream at a frequency of approximately 1 every 35 samples. · Field duplicates collected at a ration 1:25. · Quality control data has been plotted on charts with control limits at · +/-1σ, +/- 2σ and +/-3σ standard deviations to monitor the level of · contamination, accuracy, and precision. · QAQC report reviewing field duplicate imprecision (C.V.), field duplicate bias, blanks and CRM actual deviation and lab pulp sizing compiled immediately after laboratory results were received. · All QAQC results have been reviewed by the ARV Competent Person who considers the results to be within acceptable limits. Therefore, the assay results presented are considered accurate and correct. · ALS internal CRMs and duplicates have also reported prior to release of finalised certificates. |

| Verification of sampling and assaying | · The verification of significant intersections by either independent or alternative company personnel. · The use of twinned holes. · Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. · Discuss any adjustment to assay data. | RC Drilling · The significant intersections have been reviewed by other ARV geologists. · No hole twinning has been undertaken · All sampling and analytical data has been stored directly into an in- house developed Access data management system, · All data has been maintained, validated, and managed by administrative geologist, · Analytical results received from the lab have been loaded directly into the database with no manual transcription of these results undertaken, · Original lab certificates have been stored electronically. No adjustment to assay data has been undertaken. Below detection limit data presented as 1/2 of the lower detection limit of the method and over the detection limit results presented as the upper detection limit of the method

|

| Location of data points | · Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. · Specification of the grid system used. Quality and adequacy of topographic control. | RC Drilling · Drill collar locations have been set with handheld GPS (+/-3 m) and collar orientation using Reflex survey method, · During drilling, down hole surveys at every 5 or 10m intervals have been completed using north seeking Gyro. · All locations recorded using GDA94/MGA UTM Zone 50.

|

| Data spacing and distribution | · Data spacing for reporting of Exploration Results. · Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. Whether sample compositing has been applied. | RC Drilling · Drill holes are continuously sampled from top of hole to end of hole. · Sections are orientated 45 to the North and approximately. · Drill holes are inclined approximately -60 from the horizontal. · The spacing and distribution of the current drill holes is considered sufficient for the testing of specific targets. · This spacing for the holes reported is not adequate to result in a resource estimate. · Drill samples were taken at 1m intervals or composited over 2m intervals prior to being submitted to the laboratory, honouring geological contacts, state of oxidation-weathering and observable mineralisation.

|

| Orientation of data in relation to geological structure | · Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. | RC Drilling · The regional stratigraphy has a steep southerly dip and the contained mineralisation comprising the Titan East prospect has an interpretive steep southerly dip and drilling orientated 45o to the Northeast with a hole inclination of 60deg. · The true orientation of potential mineralised bodies in this area is poorly understood.

|

| Sample security | The measures taken to ensure sample security. | · Sample security is by way of chain of custody. · All drill samples collected during the program are freighted by road transport directly to the ALS laboratory in Perth for submission. Sample security was not considered a significant risk to the project. Only employees of Artemis Resources and APEX Geoscience were involved in the collection, short term storage (in a remote area), and delivery of samples. |

| Audits or reviews | The results of any audits or reviews of sampling techniques and data. | No review of the sampling techniques has been undertaken. |

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section)

| Criteria | JORC Code explanation | Commentary |

| Mineral tenement and land tenure status | · Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. | · The RC program was entirely conducted on E47/1797. · All Artemis Project tenures are 100% owned by Artemis Resources subsidiary company KML No 2 Pty Ltd E47/1746 & E47/1797 with the exception of E47/3719 which is subject to a GreenTech Metals/Artemis Resources 51%/49% Joint Venture Tenements are in good standing with DEMIRS and there are no known impediments for exploration on these tenements. |

| Exploration done by other parties | Acknowledgment and appraisal of exploration by other parties. | Previous explorers in the region include but not limited to are Westfield Minerals, Consolidated Gold Areas, Open Pit Mining and Exploration, Legend Mining, Agip Exploration, Titan Resources and Fox Resources. |

| Geology | Deposit type, geological setting and style of mineralisation. | Surface mineralisation is interpreted to be consistent with structurally controlled shear zone mineralisation. Implications for intrusion related mineralised systems is also considered. |

| Drill hole Information | · A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes: o easting and northing of the drill hole collar o elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar o dip and azimuth of the hole o down hole length and interception depth o hole length. If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case. | · Drill hole collar locations are recorded in the body of the release. · Drilling was conducted at the natural land surface. Elevations of drill holes have been obtained by handheld GPS. · Hole 25ARRC006 was drilled to 162m and 25ARRC024 was drilled to 140m. Laboratory analyses have been partially completed on all the samples collected from the drilling to date, 25ARRC006 has had all laboratory analyses completed and certified. |

| |

|

|

| Data aggregation methods | In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated. •Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. •The assumptions used for any reporting of metal equivalent values should be clearly stated.

| Not applicable as no data aggregation has been used. |

| Relationship between Mineralisation widths and intercept lengths | These relationships are particularly important in the reporting of exploration results · In the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. · If it is not known and the only down hole lengths are reported, there should be a clear statement to this effect (eg. Down hole length, true width not known)

| RC Drilling · The hoels drilled were exploration in nature · Downlhole length only reported, true width is not known. |

| Diagrams | Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views. | All the appropriate maps are provided in the body of this announcement Refer to figures and tables in the body of the ASX release. While significant results have been highlighted in accompanying Tables, the reconnaissance nature of much of the RC may result in many holes containing no significant intersections. |

| Balanced reporting | · Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. | This announcement discusses the findings of completed RC drilling activities and certified assays returned 27/10/2025. |

| Other substantive exploration data | Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. | · Previous drilling completed by Artemis Resources Titan East Prospect · Total of 3 drill holes for 548.2m completed at Titan East prospect best intercept at Titan East prior to this release included 25ARDD004 - 1m @ 16.4gpt Au from 67m; (refer to ASX release 28th April 2025)

|

| Further work | · The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling). · Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. | Diamond and RC drilling to commence shortly at Carlow licence to test orientation of interpreted shear zone, and follow up the high grade intersection in 25ARRC006 |

[1] Refer ARV ASX announcement on 13 October 2022

RNS may use your IP address to confirm compliance with the terms and conditions, to analyse how you engage with the information contained in this communication, and to share such analysis on an anonymised basis with others as part of our commercial services. For further information about how RNS and the London Stock Exchange use the personal data you provide us, please see our Privacy Policy.