PRESS RELEASE

17 June 2025

KAVANGO RESOURCES PLC

("Kavango" or "the Company")

ZIM: Steenbok Encouraging High-Grade Assays

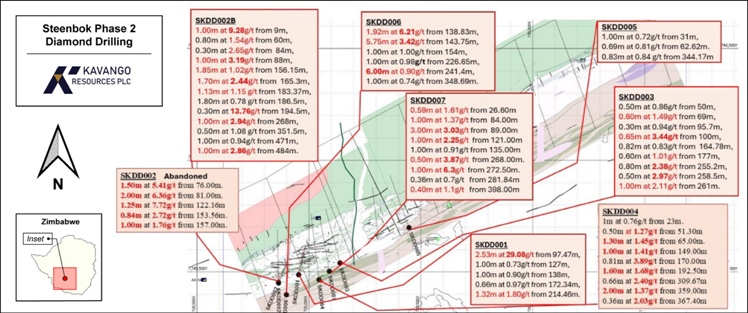

Kavango Resources plc (LSE: KAV), the Southern Africa focused metals exploration and gold production company, is pleased to announce further significant gold intercepts at the Prospect 4 Steenbok Target ("Steenbok") in the Hillside Project ("Hillside"), Zimbabwe. Kavango completed a further 3,232m of diamond drilling at Steenbok, which built upon the success of Hole SKDD001 (announced >>> April 2024).

Seven of the eight holes drilled intersected encouraging gold mineralisation.

In total, there were 69 significant gold intersections using a cut-off grade of 0.7g/t Au (the "Significant Intersections"). Of these, there were 41 intersections with grade >1g/t.

In parallel to drilling, Kavango employed a firm of specialist structural geologists to review the geological setting at Steenbok. Based upon the extent of the claims, geological mapping and the structural review the Company believes the strike length at Steenbok is up to 1.5km long and open in both directions.

Highlights

· Kavango has drilled a total of 3,479m across 8 diamond core holes at Steenbok. This includes the original discovery hole SKDD001, which returned 2.53m @ 29.08grams/tonne of gold ("g/t Au")

· High-grade gold intersections in 6 of the 7 new holes

· 41 significant gold intersections, grading at >1g/t Au, intercepted across 400m of strike that is open in both directions. Highlights include:

· Hole SKDD002:

· 1.5m @ 5.41g/t from 76m (including 0.8m @ 7.25g/t Au from 76.7m),

· 2m @ 6.36g/t Au from 81m,

· 1.25m @ 7.72g/t Au from 122.16m (including 0.4m @ 19.29g/t Au).

· Hole SKDD002B:

· 1m @ 9.28g/t Au from 9m,

· 1m @ 3.19g/t Au from 88m,

· 1.7m @ 2.44g/t from 165.3m,

· 1m @ 2.94g/t Au from 268m.

· Hole SKDD004:

· 2m @ 1.37g/t Au from 359m.

· Hole SKDD006:

· 1.92m @ 6.21g/t Au from 138.83m (including 0.5m @ 17.78g/t),

· 5.75m @ 3.42 g/t from 143.7m (including 1m @ 13.29g/t Au),

· 1m @ 2.49g/t Au from 243.4m.

· Hole SKDD007:

· 3m @ 3.03g/t from 91m (including 1m @ 7.78g/t Au),

· 1m @ 6.3g/t Au from 272.5m

· The distribution and tenor of these intercepts supports Kavango's interpretation of Steenbok as a structurally hosted vein system, comparable to high-grade shear-hosted gold systems of Western Australia.

· Based on geological mapping and internal calculations of the extent, Kavango believes total strike of the system to be at least 1.5km.

· Murgana Geological Consulting Ltd. (Murgana), a firm of specialist structural geologists, employed to review the structural settings across the Hillside Project conclude the ore mineralisation is structurally controlled by a D2M2 related network of shear zones that were acting as feeders but also as traps for the hydrothermal alteration and related Au mineralisation.

· Kavango is now preparing to follow up exploration and drill programs at Steenbok, including geotechnical drilling to assess rock competency and support possible future mining operations.

Ben Turney, Chief Executive Officer of Kavango Resources, commented:

"As Kavango moves towards much more significant mining, these results from Steenbok mark a highly encouraging continuation of our work in this emerging gold system. We deliberately targeted 400m of strike and are delighted to confirm this portion is gold mineralised throughout and open in both directions.

With strong gold grades encountered in 6 of the 7 holes we drilled and confirmation of the structural controls, we are making real progress in building a robust geological model. Following additional work by Murgana, it appears that the strike length at Steenbok is up to 1.5km long and open in both directions.

The comparison with gold systems seen in Australia is exciting and validates our ongoing strategy. We look forward to commencing geotechnical drilling shortly as we move towards a potential development decision."

Renaming of Prospects

To improve operational clarity, Kavango has reverted to using the historic names of the first four gold prospects at its Hillside Project ("Hillside") in southern Zimbabwe. The names - Bill's Luck, Britain, Nightshift, and Steenbok - apply to the previous internal references of Prospect 1, 2, 3, and 4 respectively.

These names reflect the Company's advancing geological understanding of Hillside and will now be adopted in all technical reporting, investor updates, and operational planning.

· New prospect names assigned at Hillside:

▪ Prospect 1 is now Bill's Luck

▪ Prospect 2 is now Britain

▪ Prospect 3 is now Nightshift

▪ Prospect 4 is now Steenbok

The historic mine names are already in use by Kavango's field teams and align with both historical data references and current drilling zones.

Drilling at Steenbok

At the start of 2025, Kavango drilled 3,232m of diamond core holes across seven new holes at Steenbok. This brings the total drilled at Steenbok to 3,479m. This programme built on the previously announced Hole SKDD001 (April 2024). SKDD001 returned 2.53m @ 29.08g/t Au and followed a successful soil sampling and mapping campaign completed in 1H 2024.

Gold mineralisation at Steenbok is structurally controlled, with grade associated with, but not necessarily confined to, a network of subvertical, anastomosing shear zones, similar to that seen in Western Australia's goldfields.

Kavango targeted 400m of strike with 6 of the holes that were drilled (SKDD001, SKDD002B, SKDD003, SKDD004, SKDD006 and SKDD007). Hole SKDD002 was abandoned and redrilled at the driller's expense as SKDD002B. All 6 completed holes, and the abandoned hole, intersected significant gold mineralisation throughout (from near surface to end of hole).

Drilling intersected 69 significant gold intersections using a cut-off grade of 0.7g/t Au. Of these, there were 41 intersections with grade >1g/t.

FIGURE 01 - Map showing diamond drill hole locations and gold mineralisation intercept highlights

Hole SKDD005 was designed as a step out hole, to test for the strike extent. Following the report from Murgana, the Company has updated its interpretation of the strike and is assessing alternative collar locations to test the strike more accurately.

Table 1: Table of diamond holes drilled at Steenbok

| No. | Drill Rig | Plan ID | Easting | Northing | RL | Azimuth | Dip | EOH (m) | year |

| 1 | Equity | SKDD001 | 728961 | 7745489 | 1113 | 8 | -60 | 247.40 | 2024 |

| 2 | Equity | SKDD002 | 728871 | 7745454 | 1114 | 22 | -60 | 163.75 | 2025 |

| 3 | Equity | SKDD002B | 728872 | 7745452 | 1114 | 2 | -65 | 502.50 | 2025 |

| 4 | Equity | SKDD003 | 729146 | 7745542 | 1106 | 350 | -65 | 502.50 | 2025 |

| 5 | Equity | SKDD004 | 729053 | 7745471 | 1108 | 350 | -67 | 451.06 | 2025 |

| 6 | Equity | SKDD006 | 729451 | 7745701 | 1113 | 335 | -65 | 637.40 | 2025 |

| 7 | Spartan | SKDD005 | 728907 | 7745402 | 1109 | 4 | -65 | 449.84 | 2025 |

| 8 | Spartan | SKDD007 | 729101 | 7745503 | 1107 | 350 | -65 | 524.84 | 2025 |

Table 2: Table of significant intercepts using a 0.7g/t Au cut-off.

| Hole ID | from | to | length | Au g/t | comments |

| SKDD001 | 97.47 | 100.00 | 2.53 | 29.08 | includes 1m at 212.07 g/t |

| SKDD001 | 127.00 | 128.00 | 1.00 | 0.73 | |

| SKDD001 | 138.00 | 139.00 | 1.00 | 0.90 | |

| SKDD001 | 172.34 | 173.00 | 0.66 | 0.97 | |

| SKDD001 | 214.46 | 215.78 | 1.32 | 1.80 | |

| SKDD002 | 76.00 | 77.50 | 1.50 | 5.41 | includes 0.8m at 7.25g/t |

| SKDD002 | 81.00 | 83.00 | 2.00 | 6.36 | |

| SKDD002 | 89.90 | 90.20 | 0.30 | 0.79 | |

| SKDD002 | 122.16 | 123.41 | 1.25 | 7.72 | includes 0.4m at 19.29g/t |

| SKDD002 | 148.00 | 148.40 | 0.40 | 0.98 | |

| SKDD002 | 150.00 | 151.00 | 1.00 | 0.87 | |

| SKDD002 | 153.56 | 154.40 | 0.84 | 2.72 | |

| SKDD002 | 157.00 | 158.00 | 1.00 | 1.76 | |

| SKDD002B | 9.00 | 10.00 | 1.00 | 9.28 | |

| SKDD002B | 13.50 | 14.35 | 0.85 | 0.83 | |

| SKDD002B | 60.00 | 60.80 | 0.80 | 1.54 | |

| SKDD002B | 84.00 | 84.30 | 0.30 | 2.65 | |

| SKDD002B | 88.00 | 89.00 | 1.00 | 3.19 | |

| SKDD002B | 122.15 | 122.45 | 0.30 | 0.83 | |

| SKDD002B | 125.00 | 125.42 | 0.42 | 0.72 | |

| SKDD002B | 149.95 | 150.70 | 0.75 | 0.86 | |

| SKDD002B | 156.15 | 158.00 | 1.85 | 1.02 | |

| SKDD002B | 165.30 | 167.00 | 1.70 | 2.44 | |

| SKDD002B | 172.50 | 173.00 | 0.50 | 0.96 | |

| SKDD002B | 183.37 | 184.50 | 1.13 | 1.15 | |

| SKDD002B | 186.50 | 188.30 | 1.80 | 0.78 | |

| SKDD002B | 190.50 | 191.00 | 0.50 | 0.74 | |

| SKDD002B | 194.85 | 195.15 | 0.30 | 13.76 | |

| SKDD002B | 268.00 | 269.00 | 1.00 | 2.94 | |

| SKDD002B | 323.50 | 324.00 | 0.50 | 0.74 | |

| SKDD002B | 349.62 | 349.95 | 0.33 | 0.85 | |

| SKDD002B | 351.50 | 352.00 | 0.50 | 1.08 | |

| SKDD002B | 471.00 | 472.00 | 1.00 | 0.94 | |

| SKDD002B | 484.00 | 485.00 | 1.00 | 2.86 | |

| SKDD003 | 50.00 | 50.50 | 0.50 | 0.86 | |

| SKDD003 | 69.00 | 69.60 | 0.60 | 1.49 | |

| SKDD003 | 95.70 | 96.00 | 0.30 | 0.94 | |

| SKDD003 | 100.00 | 100.65 | 0.65 | 3.44 | |

| SKDD003 | 164.78 | 165.60 | 0.82 | 0.83 | |

| SKDD003 | 177.00 | 177.60 | 0.60 | 1.01 | |

| SKDD003 | 255.20 | 256.00 | 0.80 | 2.38 | |

| SKDD003 | 258.50 | 259.00 | 0.50 | 2.97 | |

| SKDD003 | 261.00 | 262.00 | 1.00 | 2.11 | |

| SKDD004 | 2.00 | 3.00 | 1.00 | 0.76 | |

| SKDD004 | 51.30 | 51.80 | 0.50 | 1.27 | |

| SKDD004 | 65.00 | 66.30 | 1.30 | 1.45 | |

| SKDD004 | 77.40 | 78.40 | 1.00 | 0.75 | |

| SKDD004 | 149.00 | 150.00 | 1.00 | 1.41 | |

| SKDD004 | 170.00 | 170.81 | 0.81 | 3.89 | |

| SKDD004 | 189.85 | 190.22 | 0.37 | 1.01 | |

| SKDD004 | 192.50 | 194.10 | 1.60 | 1.68 | includes 0.69m at 2.72g/t |

| SKDD004 | 309.67 | 310.33 | 0.66 | 2.40 | |

| SKDD004 | 347.00 | 348.00 | 1.00 | 0.84 | |

| SKDD004 | 359.00 | 361.00 | 2.00 | 1.37 | |

| SKDD004 | 363.00 | 364.00 | 1.00 | 0.78 | |

| SKDD004 | 367.40 | 367.76 | 0.36 | 2.03 | |

| SKDD005 | 31.00 | 32.00 | 1.00 | 0.72 | |

| SKDD005 | 62.62 | 63.31 | 0.69 | 0.81 | |

| SKDD005 | 344.17 | 345.00 | 0.83 | 0.84 | |

| SKDD006 | 138.83 | 140.75 | 1.92 | 6.21 | includes 0.5m at 17.78g/t and 0.5m at 3.26g/t |

| SKDD006 | 143.75 | 149.50 | 5.75 | 3.42 | includes 1.0m at 13.29g/t and 0.5m at 6.04g/t |

| SKDD006 | 154.00 | 155.00 | 1.00 | 1.00 | |

| SKDD006 | 226.65 | 227.65 | 1.00 | 0.98 | |

| SKDD006 | 241.40 | 247.40 | 6.00 | 0.90 | includes 1.0m at 2.49g/t |

| SKDD006 | 348.69 | 349.69 | 1.00 | 0.74 | |

Structural assessment of Steenbok and next steps

Recent fieldwork by structural consultants Murgana has proved invaluable in improving Kavango's understanding of the manner of the vein systems, and the team continues to work on its characterisation of gold mineralisation, and the surrounding geology at Steenbok to develop a robust geological model ahead of any decision to develop the project. Based on geological mapping and internal calculations of the extent, Kavango believes total strike of the system to be at least 1.5km. Kavango is now working on an exploration plan to test whether this strike is gold mineralised.

To this end, the next phase of development at Steenbok will include further exploration to gather more data on the gold mineralised system and a number of geotechnical holes to assess rock competency and assist possible future underground operations. These will inform further development planning, building on the current drilling and structural model.

Further updates on the Hillside Project, including additional assay results and drilling progress, will follow shortly.

Further information in respect of the Company and its business interests is provided on the Company's website at www.kavangoresources.com and on Twitter at #KAV.

For further information please contact:

Kavango Resources plc

Ben Turney

+46 7697 406 06

First Equity (Broker)

+44 207 374 2212

Jason Robertson

Kavango Competent Person Statement

The technical information contained in this announcement pertaining to geology and exploration have been compiled by Mr David Catterall, a Competent Person and a member of a Recognised Professional Organisations (ROPO). David Catterall has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (JORC 2012). David is the principal geologist at Tulia Blueclay Limited and a consultant to Kavango Resources. David Catterall is a member of the South African Council for Natural Scientific Professions, a recognised professional organisation.

Kavango Resources plc Sampling Techniques and Data for Hillside Project Diamond Drilling. Zimbabwe

Last updated: 15 June 2025

(Criteria in this section apply to all succeeding sections)

JORC Code. 2012 Edition - Table 1 reportSection 1 Sampling Techniques and Data(Criteria in this section apply to all succeeding sections.) | ||

| Criteria | JORC Code explanation | Commentary |

| Sampling techniques | Nature and quality of sampling (e.g. cut channels. random chips. or specific specialised industry standard measurement tools appropriate to the minerals under investigation. such as down hole gamma sondes. or handheld XRF instruments. etc). These examples should not be taken as limiting the broad meaning of sampling. | · The information in this release relates to the technical details from the Company's exploration and drilling program at Hillside Project which lies within the Filabusi Greenstone Belt, Matabeleland, Zimbabwe. · Diamond drilling (HQ & NQ) was carried out and half core samples were taken from the entire hole. · Core was cut into two using a commercial core saw adjacent to the Ori line to produce two splits as mirror images with regards to igneous textures, sedimentary bedding where possible structural fabric. · Samples were taken based on geological contacts, and/or of up to approximately 1m in length. The minimum sample width is 30cm to cater for distinct quartz veins which may be diluted and obscured if 1m widths were to be maintained. · Samples were submitted for a 25g fire assay with AAS finish. to Performance Laboratories (Pvt) Ltd., at Harare, Zimbabwe. · Selected samples will be sent to a check lab, ALS laboratories, Johannesburg, for referee fire assay comparison. · Kavango routinely takes pXRF readings along the core using an Olympus Vanta on Geochem 3 beam mode 60 seconds. |

| Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used | · All Kavango's diamond core samples were geologically logged by suitably qualified geologists on site. · Sample representativity was ensured where possible by drilling perpendicular to structures of interest, and by the sample preparation technique in the laboratory. · The entire borehole diamond drill core was sampled based on geological logging, with the ideal sampling interval being 1m, whilst ensuring that sample interval does not cross any logged feature of interest (e.g. lithological contact. alteration. mineralisation or structure). · Individual core samples are weighed at the field camp. · Upon arrival at Performance lab, the samples are dried at +/- 105 deg Celsius for 8 to 12 hours. · Entire sample is crushed to 100% passing 4.75mm. The crushers have inline rotary splitters that split off 500g of sample that is pulverized. · The 500g split is pulverized in a Rocklabs pot and puck pulveriser with 85% passing minus 75μm. · A standard 25g aliquot is used for Fire Assay. · Following industry best practice. a series of certified reference materials (CRM's), duplicates and blanks were included for QAQC as outlined further below. | |

| Aspects of the determination of mineralisation that are Material to the Public Report. | ||

| In cases where 'industry standard' work has been done this would be relatively simple (e.g. 'reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay'). In other cases. more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (e.g. submarine nodules) may warrant disclosure of detailed information. | ||

| Drilling techniques | Drill type (e.g. core. reverse circulation. open-hole hammer. rotary air blast. auger. Bangka. sonic. etc) and details (e.g. core diameter. triple or standard tube. depth of diamond tails. face-sampling bit or other type. whether core is oriented and if so. by what method. etc). | · Each hole was drilled using a diamond drill operated by Equity Drilling Limited and Spartan Drilling Services. · Both Equity and Spartan use HQ and NQ diameter conventional core barrel.

|

| Drill sample recovery | Method of recording and assessing core and chip sample recoveries and results assessed. | · Core recovery was monitored closely throughout. · Recovery in rock was >95%. · Any voids were noted. |

| Measures taken to maximise sample recovery and ensure representative nature of the samples. | · Samples prepared for assay are taken consistently from the same side of the core cutting line to avoid bias. · Geologists frequently check the core cutting procedures to ensure the core cutter splits the core correctly in half. · Core samples for assay are selected within logged geological, structural, mineralisation and alteration constraints. · Samples are collected from distinct geological domains with sufficient width to avoid overbias. | |

| Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. | · For Diamond drilling sample recovery was generally very good and as such it is not expected that any such bias exists. | |

| Logging | Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation. mining studies and metallurgical studies. | · Kavango's Diamond drill core samples are logged by a team of qualified geologists using predefined lithological, mineralogical, physical characteristic (colour, weathering etc) and logging codes. · Diamond drill core was marked up on site and Geotechnical logging was completed at the rig to ensure recoveries were adequately recorded. · Lithological, structural, alteration and mineralisation are logged at camp · The core is securely stored at the base camp. · The geologists on site follow industry best practice and standard operating procedure for diamond core drilling processes. · The core is photographed wet and dry with pXRF and magnetic susceptibility data also captured. · Density measurements were determined by Archimedes density measurements i.e. using a precision balance to weigh sample in air and in submerged in water. A representative piece of core was selected from each sample for density measurement. · The QA/QC compilation of all logging results are stored and backed up on a data cloud. |

| Whether logging is qualitative or quantitative in nature. Core (or costean. channel. etc) photography. | · All logging is conducted in accordance with Kavango's SOP and standard published logging charts and classification for grain size, abundance, colour and lithologies to maintain a qualitative and semi-quantitative standard based on visual estimation. · Magnetic susceptibility readings are also taken every metre and/or half metre using a ZH Instruments SM-20/SM-30 reader. · All core drilled was photographed wet and dry according to industry best practice. | |

| The total length and percentage of the relevant intersections logged. | · 100% of all recovered intervals are geologically logged. | |

| Sub-sampling techniques and sample preparation | If core. whether cut or sawn and whether quarter. half or all cores taken. | · Selected intervals are cut in half with a commercial core cutter. using a 2mm thick blade · One half is sampled for analysis while the other half is kept for reference. · Some of the retained half core is submitted for metallurgical test work. · For selected petrographic samples core is quartered. |

| If non-core. whether riffled. tube sampled. rotary split. etc and whether sampled wet or dry | · All drilling to date has been diamond drilling. | |

| For all sample types. the nature. quality and appropriateness of the sample preparation techniques | · Field sample preparation is suitable for the core samples. · The laboratory sample preparation technique is considered appropriate and suitable for the core samples and expected grades. | |

| Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. | · Kavango's standard field QAQC procedures for drilling samples include the field insertion of blanks, an appropriate selection of standards, field duplicates, replicates, and selection of requested laboratory pulp and coarse crush duplicates. · These are being inserted at a rate of 2.5- 5% each to ensure an appropriate rate of QAQC. | |

| Measures taken to ensure that the sampling is representative of the in-situ material collected. including for instance results for field duplicate/second-half sampling. | · Sampling is deemed appropriate for the type of survey and equipment used. · Quarter core duplicates are not deemed appropriate for this type of gold mineralisation. This could potentially bias the sample due to the nugget effect and vein hosted nature of the mineralisation and would reduce the sample volume. · Laboratory duplicates are produced from the crushed and milled core. | |

| Whether sample sizes are appropriate to the grain size of the material being sampled. | · On occasions gold from this project may be coarse, therefore, some nugget effect is expected. This is minimised by using the largest diameter of core possible with the available equipment, and by utilising halved rather than quartered core for assay. | |

| Quality of assay data and laboratory tests | The nature. quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. | · A company audit was made of the assay laboratory in this case Performance Laboratories before it was engaged. · The digest and fire assay technique provide a total analysis method. · Between 5% and 20% of submitted samples consisted of additional blank, duplicate (lab duplicate from splitting the pulp), and standard samples. · Round robin and accreditation results for the laboratory were reviewed and considered acceptable. · The company's QAQC samples, including standards, are considered to confirm acceptable bias and precision with no contamination issues identified. |

| For geophysical tools. spectrometers. handheld XRF instruments. etc. the parameters used in determining the analysis including instrument make and model. reading times. calibrations factors applied and their derivation. etc.

Nature of quality control procedures adopted (e.g. standards. blanks. duplicates. external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established. | · Kavango use ZH Instruments SM20 and SM30 magnetic susceptibility meters for measuring magnetic susceptibilities and readings are randomly repeated to ensure reproducibility and consistency of the data. · An Olympus Vanta C-series pXRF instrument is used in 3-beam geochemical mode with reading times of 60 seconds in total. Measurements are taken on clean dry core. · For the pXRF results no user factor was applied as per Kavango's SOP. The units are calibrated daily with their respective calibration disks. · All QAQC samples were reviewed for precision and accuracy. Results were deemed repeatable and representative: · For pXRF appropriate certified reference materials are inserted on a ratio of 1:25 samples. · Repeat readings are taken every 25 samples. and blank samples are inserted every 25 samples. · QAQC samples are reviewed for consistency. · pXRF CRM values show a slight positive bias. including for Cu. · At low levels (<10ppm) silver values in particular are scattered. · When laboratory assay results are received blank, standard, and duplicate values are reviewed to monitor lab performance. | |

|

| · Performance Lab insert their own CRM's, duplicates and blanks and follow their own SOP for quality control. · External referee laboratory checks will be carried out as and when sufficient holes have been drilled to warrant. | |

| Verification of sampling and assaying | The verification of significant intersections by either independent or alternative company personnel. | · All drill core intersections were verified by peer review. · The Company's internal CP reviewed sampling and has visited site and the laboratory to verify protocols. · Assay data was received as assay certificates and cross checked against sample submission data to ensure a correct match. |

| The use of twinned holes. | · No twinned holes have been drilled to date. | |

| Documentation of primary data. data entry procedures. data verification. data storage (physical and electronic) protocols. | · All data is electronically stored with peer review of data processing and modelling. · Data entry procedures standardized in SOP data checking and verification routine. · Data storage is on a cloud storage facility with access controls and automatic backups. | |

| Discuss any adjustment to assay data. | · No adjustments were made to assay data. | |

| Location of data points | Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys). trenches. mine workings and other locations used in Mineral Resource estimation. | · Kavango's drill collar coordinates are captured by using handheld Garmin GPS and verified by a second handheld Garmin GPS. · Drill holes are routinely re-surveyed with differential DGPS at regular intervals to ensure sub-metre accuracy as and when sufficient holes warrant. · Downhole surveys of drill holes were done using an AXIS Champ Mag tool or the Champ Gyro (for DTH). |

| Specification of the grid system used. | · The grid system used is UTM 35S Arc 1950. All reported coordinates are referenced to this grid. | |

| Quality and adequacy of topographic control. | · Topographic control is based on satellite survey data collected at 30m resolution. Quality is considered acceptable. | |

| Data spacing and distribution | Data spacing for reporting of Exploration Results. Whether the data spacing. and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. | · Data spacing and distribution of all survey types is deemed appropriate for the type of survey and equipment used. · A series of step out holes drilled along strike with drill hole spacing between 50m to 100m except for one hole where it is 300m. · The program is designed to target the multiple (sheeted) auriferous veins at the IXL Mine on the Prospect Claims.

|

| Whether sample compositing has been applied. | · N/A | |

| Orientation of data in relation to geological structure | Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known. considering the deposit type. | · Drill spacing is currently 50m to 100m between holes except for one hole where it is 300m. This is considered appropriate for this stage of exploration. · Hole orientation is designed to intersect the target structures as perpendicular as is practical. · This is considered appropriate for the geological setting and for the known mineralisation styles. |

| If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias. this should be assessed and reported if material. | · Existence, and orientation of preferentially mineralised structures is not yet fully understood but current available data indicates mineralisation occurs within steep. sub-vertical structures. · The drillholes are inclined towards the target, which is understood to dip towards the drillhole at a steep angle (actual geometry to be confirmed by a second hole on section in the future). · The relatively short sample length (typically 1 m) allows for relatively accurate localization of mineralisation. · No significant sampling bias is therefore expected. | |

| Sample security | The measures taken to ensure sample security. | · Diamond core is stored in a secure facility at the field office. · Sample bags are logged, tagged, double bagged and sealed in plastic bags stored at the field office. · Samples are stored in a locked company compound at site and in a locked container in Bulawayo. They are shipped onwards to the analytical facility by a reliable commercial courier. · Sample security includes a chain-of-custody procedure that consists of filling out sample submittal forms that are sent to the laboratory with sample shipments to make certain that all samples are received by the laboratory. · Prepared samples are transported to the analytical laboratory in sealed bags that are accompanied by appropriate paperwork. including the original sample preparation request numbers and chain-of-custody forms. |

| Audits or reviews | The results of any audits or reviews of sampling techniques and data. | · The CP has visited both site and the laboratory utilised and considered practices and SOPs at both as acceptable. · The CP reviewed all data, and spot-checked significant values versus certificates. |

JORC Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

| Criteria | JORC Code explanation | Commentary | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mineral tenement and land tenure status | Type. reference name/number. location and ownership including agreements or material issues with third parties such as joint ventures. partnerships. overriding royalties. native title interests. historical sites. wilderness or national park and environmental settings. The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. | · The Hillside Project consists of 44 gold claims. · Kavango entered into an option agreement with the vendors, dated 25 July 2023. · This was exercised on 23 April 2024 with respect to Hillside and Leopard South. · Leopard North remains subject to a call option valid to June 2025. · Transfer of the Claims is presently underway. · More details are provided here https://polaris.brighterir.com/public/kavango_resources_plc/news/rns/story/w9nq44r | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Exploration done by other parties | Acknowledgment and appraisal of exploration by other parties. | · The project contains a historic high-grade mine (IXL) that has been discontinuously mining gold since 1910. · It is currently being mined by artisanal miners, who are under contract, milling the ore at Bill's Luck stamp mill. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Geology | Deposit type. geological setting and style of mineralisation. | · Steenbok lies near the NW contact of the Filabusi gold belt and the Bulawayan Basement Schists. Younger intrusive granites bound it to the north. · Gold mineralization is associated with multiple sub parallel quartz veins that occur in fine grained massive sheared granite and in leucogranite / metavolcanics. · The general azimuth of the auriferous veins is 90o to 100o TN (dipping steeply to the SSW) while foliation within the fine-grained granite and lucogranite is between 65o to 75o TN dipping sub vertical. · Major structures close to the IXL mine are the Umzingwane Shear zone, the Irisvale-Lancaster Shear Zone and the Cleavage Divide. · Historical gold production figures (1910 to 1929) amounts to 154,148 grams at an average recovery grade of 11,56 g/t. · It is likely that these grades originated from the shallow supergene enriched oxidized zone as mention is made that most workings only went to depths of 5m with a maximum of 23m. · Based on SD Siziba's report of 1986 the area has a potential of 400,000 tonnes grading at 11 g/t Au.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Drill hole Information | A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes: easting and northing of the drill hole collar elevation or RL (Reduced Level - elevation above sea level in metres) of the drill hole collar dip and azimuth of the hole down hole length and interception depth hole length. If the exclusion of this information is justified on the basis that the information is not Material, and this exclusion does not detract from the understanding of the report. the Competent Person should clearly explain why this is the case. | · Summary table of all completed Kavango diamond drill holes that form the focus of the current program is presented below. · The holes were surveyed and sited using a handheld GPS · Upon completion of drilling a DGPS survey was completed by professional surveyors. · Position format: UTM UPS; Map datum Arc 1950 Zone 35S.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Data aggregation methods | In reporting Exploration Results. weighting averaging techniques. maximum and/or minimum grade truncations (e.g. cutting of high grades) and cut-off grades are usually Material and should be stated. Where aggregate intercepts incorporate short lengths of high-grade results and longer lengths of low-grade results. the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. The assumptions used for any reporting of metal equivalent values should be clearly stated. | · Results will be reported as and when they are available and have been reviewed for QAQC and used for interpretation

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Relationship between mineralisation widths and intercept lengths | These relationships are particularly important in the reporting of Exploration Results. If the geometry of the mineralisation with respect to the drill hole angle is known. its nature should be reported. If it is not known and only the down hole lengths are reported. there should be a clear statement to this effect (eg 'down hole length. true width not known'). | · Down hole intersection widths are used throughout. · Most of the drill intersections are into steep to vertically dipping units. True thickness is presently unknown and will be determined based on additional drilling. · All measurements state that downhole lengths have been used as the true width cannot yet be established by the current drilling. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Diagrams | Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include. but not be limited to a plan view of drill hole collar locations and appropriate sectional views. | · N/A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Balanced reporting | Where comprehensive reporting of all Exploration Results is not practicable. representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. | · All core is presently being logged, cut and sampled for dispatch. · Results will be reported as and when they are available and have been reviewed for QAQC and used for interpretation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Other substantive exploration data | Other exploration data. if meaningful and material. should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples - size and method of treatment; metallurgical test results; bulk density. groundwater. geotechnical and rock characteristics; potential deleterious or contaminating substances. | · Soil sampling at Steenbok was completed on the 16th May 2024 with 589 samples collected. All samples were scanned by pXRF. Samples were analysed at Performance by bottle roll (a Bulk Leach Extraction Method: BLEG)

· Geophysical work has been done previously, comprising Gradient Array IP and Stacked Schlumberger Sections | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Further work | The nature and scale of planned further work (e.g. tests for lateral extensions or depth extensions or large-scale step- out drilling). Diagrams clearly highlighting the areas of possible extensions. including the main geological interpretations and future drilling areas. provided this information is not commercially sensitive | · N/A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

RNS may use your IP address to confirm compliance with the terms and conditions, to analyse how you engage with the information contained in this communication, and to share such analysis on an anonymised basis with others as part of our commercial services. For further information about how RNS and the London Stock Exchange use the personal data you provide us, please see our Privacy Policy.